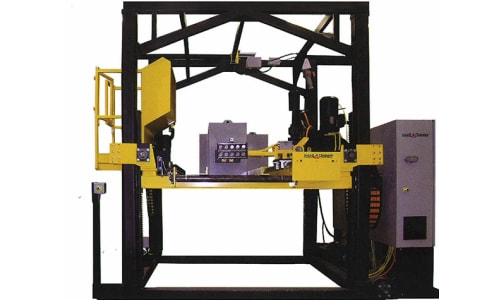

MAN-ABOARD POWER CHANGER EQUIPMENT

MTC’s industry-leading Power Changers provide the increased power, capacity and multi-functionality required by larger fleets. MTC’s power changer equipment includes Single and Multi-Level Power Changers as well as the fully automated Intell-A-Changers. MTC’s Power Changers provide a safe and dependable way to change batteries quickly and efficiently without causing operator fatigue. MTC’s Power Changers are safe and easy to operate, while their heavy-duty design ensures reliability and durability.